(PDF) High pressure grinding rolls scaleup and

Lowpurity hematite was crushed with high pressure grinding roll, and effects of operating factors such as roller surface pressure and speed, and ore moisture content on size of crashed products

WhatsApp)

WhatsApp)

Lowpurity hematite was crushed with high pressure grinding roll, and effects of operating factors such as roller surface pressure and speed, and ore moisture content on size of crashed products

High pressure roll grinding is normally used as super fine crushing processwhich can be as the third or fourth stage of a crushing process, also can be used in the semiautogenous grinding process for hard rocks. The input material size for HPGR normally is

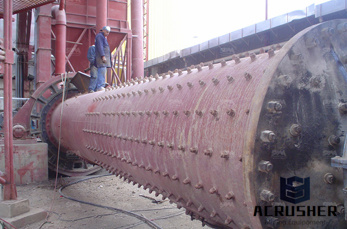

Used in mining applications for the last 30 years, high pressure grinding rolls (HPGR) reduce particles by compressing and crushing the feed between two counter rotating, parallel rollers with a small gap between them. This forces the rocks against each other and compresses the feeds density to 80% of its solid volume, exceeding its compressive

#0183;#32;High pressure grinding roll (HPGR) technology is very rapidly gaining a wide acceptance within the mineral processing industry. Benefits, including a superior energy efficiency and a lower overall operating cost of an HPGR based circuit compared to alternative technologies have been demonstrated at a number of operations throughout the world.

High pressure grinding moving ead in copper iron and . High pressure grinding moving ead in copper iron and gold processing by van der Meer and W. Maphosa Synopsis High pressure grinding roll (HPGR) technology is used in an increas ngly d verse range of appl ons predom nantly ron ore gold and diamonds.

Used in mining applications for the last 30 years, High Pressure Grinding Rolls (HPGR) reduce particles by compressing and crushing the feed between two counter rotating, parallel rollers with a small gap between them.

High Pressure Grinding Roll Features amp; Performance. The high pressure grinding roll has established itself in various industries. High pressure grinding rolls has been leading the way for the use of HPGR in the nonferrous metals mining industry. In comminution circuits of the cement and diamond industry, HPGR has become a standard grinding tool.

Coater/Roll Press Similar to Black Bros 511/4quot; wide Top amp; Bottom. Manufacturer: Black Bros Used Top amp; Bottom Coater/Roll Press (Similar to Black Bros.) to approx. 3quot; max. thickness /4quot; wide coating rolls. Grooved rolls are 71/8quot; dia. coating roll has a trough that butts up agai...

high pressure grinding roll technology. The technology used in the High Pressure Grinding Roll. (HPGR) has demonstrated that: high pressure roller press into a specific technological circuit.

High pressure grinding rolls (HPGR) are used for size reduction or rocks and ores. They compress the feed material between two rotating rollers, one of which is in a fixed position and another roller that is floating. The two rotating rollers generate such a high

used high pressure grinding roll press Description : High Pressure Grinding Roller Mill Presses Malaysia Gold With our Roller Presses, the grindin Read more. high pressure roll mill. PF Impact Crusher. By absorbing the advanced technology from the

#0183;#32;Lowpurity hematite was crushed with high pressure grinding roll, and effects of operating factors such as roller surface pressure and speed, and ore

High Pressure Grinding Rolls (HPGR) is a mature technology that is proven to reduce capital and operating costs in full scale plants when compared to other comminution technologies. Read more SGS comminution experts have developed a simple testing methodology to avoid some of the difficulties associated with using HPGR.

High Pressure Grinding With our Roller Presses, the grinding pressure is transferred from the hydraulic system via the movable roll to the material bed and absorbed in a stable, closed machine frame. A key feature is the mounting of the rollers in oillubricated cylindrical roller bearings.

High pressure grinding roll (HPGR) technology is used in an increasingly diverse range of .. frame, extracting the worn set and installing the new one (as shown in Figure 5 for a .. control of the feed rate to the roller press. At Vasilkovka the. More details

The technology''s working principle is that two counterrotating grinding rolls expose a column of material to high pressure, which is distributed across the gap between the rolls. Interparticle comminution is the HPGR specific grinding process in which material particles are crushed and ground within the compressed material bed and not by contact with the roll surface.

WhatsApp)

WhatsApp)