(PDF) Cement Manufacturing ResearchGate

Figure (5): The Wet process of cement (Masenan, 2008) Semidry process It example to dr y process and uses a L epol kiln : in the lepol kiln the pellets are dried and

WhatsApp)

WhatsApp)

Figure (5): The Wet process of cement (Masenan, 2008) Semidry process It example to dr y process and uses a L epol kiln : in the lepol kiln the pellets are dried and

For details about Basic Process of Cement Manufacturing, refer toCement Manufacturing Process

In this corporate Ohorongo video, we show you the process of making cement, from start to finish.

Three of the most important goals of any cementmaking facility is to reduce product variation, extend quarry life, and meet customer requirements. Today, there are many types of technologies available that can help cement production owners meet these goals as well as help improve product quality, boost efficiency, lower production costs, and create safer, cleaner production lines.

Simplified or conceptual designs are called process flow diagrams (PFDs). A PFD shows fewer details than a Pamp;ID and is usually the first step in the design processmore of a birds eye view. More fully developed piping and instrumentation diagrams (Pamp;IDs) are shown in a Pamp;ID.

The next step is the material being ground and becoming cement. At the final stage, cement is packaged into bags and ready to produce concrete. The first step in the process of making concrete is mixing cement, water, sand and gravel in the proportion of 15%, 10%, 25% and 50% respectively.

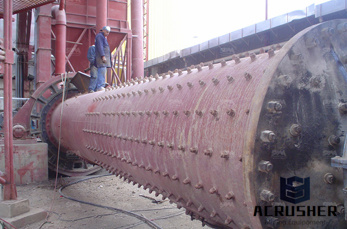

Burning: In this operation, the slurry is directly fed into a long inclined steel cylinder called a Rotary this kiln there are 3 different zones shown in fig. below. Cement Manufacturing Process Flow Chart (i) Drying Zones: In the wet process, the drying zone is comparatively larger than the dry process. It is because the raw material in slurry form is directly fed into the kiln which

The cement making process begins at our quarries. Limestone is blasted, reduced in size and then loaded. onto boats or ships to be shipped to our plants. Raw Grinding. Raw materials are offloaded at our plant docks and transported, often by. covered conveyor like

#0183;#32;Primary cementing. The objective of primary cementing is to provide zonal isolation. Cementing is the process of mixing a slurry of cement, cement additives and water and pumping it down through casing to critical points in the annulus around the casing or

Cement production processes can be categorized as dry, semidry, semiwet, and wet processes depending on the handling of raw material before being fed to the rotary kiln. Nowadays, almost all new plants are based on the dry process and many old wet plants are

A Process and Instrument Drawing (Pamp;ID) includes more details than a PFD. It includes major and minor flows, control loops and instrumentation. Pamp;ID is sometimes referred to as a Piping and Instrumentation Drawing. These diagrams are also called flowsheets.

FREE online Pamp;ID diagram drawing template enabled for the FREE online Google Docs.. Make your own Pamp;ID diagrams with this FREE online drawing tool. Log in to your Google Account (Google Accounts are free) and copy (quot;File gt; Make a copyquot;) this online Pamp;ID drawing template to start making your own drawings.. Select, copy and paste the components you want to use.

When cement block making machine was first invented, it changes the landscape of how construction projects were able to be completed. Creating cement blocks was often a very tedious process, one that would take several days just to produce a few hundred bricks.

Portland cement is the basic ingredient of concrete. Concrete is formed when portland cement creates a paste with water that binds with sand and rock to harden. Cement is manufactured through a closely controlled chemical combination of calcium, silicon, aluminum, iron and other ingredients.

Cement manufacturing is a complex process that begins with mining and then grinding raw materials that include limestone and clay, to a fine powder, called raw meal, which is then heated to a sintering temperature as high as 1450 #176;C in a cement kiln. In this process, the chemical bonds of the raw materials are broken down and then they are recombined into new compounds.

Pamp;IDs are originally drawn up at the design stage from a combination of process flow sheet data, the mechanical process equipment design, and the instrumentation engineering design. During the design stage, the diagram also provides the basis for the development of system control schemes, allowing for further safety and operational investigations, such as a Hazard and operability study (HAZOP).

#0183;#32;Cement Manufacturing Process Phase IV: Kiln Phase. Kiln is a huge rotating furnace also called as the heart of cement making process. Here, raw material is heated up to 1450 C. This temperature begins a chemical reaction so called decarbonation. In this reaction material (like limestone) releases the carbon dioxide.

Process technicians use special Pamp;IDs to identify all of the equipment, instruments, and piping found in their units. Edraw includes more than 500 standard Pamp;ID symbols used to depict industrial, process, vacuum, fluids, hydraulics, and air and gas.

WhatsApp)

WhatsApp)