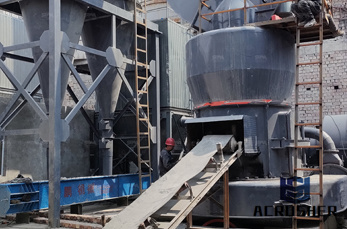

Phosphate Processing Equipment Overview

Processing Phosphates for Use in the Fertilizer Industry

WhatsApp)

WhatsApp)

Processing Phosphates for Use in the Fertilizer Industry

Phosphate Processing Equipment . Diammonium Phosphate ( DAP ) Production from Saudi Arabian . 16 Jul 2003 . . phosphate. The project and process from beneficiation to conversion is covered. . process for phosphate beneficiation Grinding Mill China . Phosphate Rock crushing process,beneficiation Phosphate Rock Introduction.

124 PHOSPHATE ROCK Phosphate processing plants are planned to triple in capacity by 2018 through construction of new Mineral Commodity Summaries, January . mining and processing of iron gold and phosphate. processing equipment for process of gold iron and phosphate extraction Mining and mineral processing .

Phosphate rock crusher is currently used mainly in two types: jaw crusher, impact crusher 1, Jaw crusher Jaw crusher is commonly used phosphate rock crushing equipment, it works with the fixed jaw plate and mobile jaw plate compression to crush phosphate, in accordance with its moving trajectory it can be divided into simple swing, complex swing and integrated swing.

By different nature of Phosphate ore, it can be divided into positive flotation, flotation (positive and negative), double reverse flotation. Shandong Xinhai Mining Technology amp; Equipment a large mining phosphorus and phosphate ore processing company. If you need phosphate rock processing machines, please contact us.

Phosphate Rock Processing Process Description15 The separation of phosphate rock from impurities and nonphosphate materials for use in fertilizer manufacture consists of beneficiation, drying or calcining at some operations, and grinding. The Standard Industrial Classification (SIC) code for phosphate rock processing is 1475. The

Phosphorite, phosphate rock or rock phosphate is a nondetrital sedimentary rock that contains high amounts of phosphate phosphate content of phosphorite (or grade of phosphate rock) varies greatly, from 4% to 20% phosphorus pentoxide (P 2 O 5).Marketed phosphate rock is enriched (quot;beneficiatedquot;) to at least 28%, often more than 30% P 2 O 5.

Phosphate rock of 70 to 75% BPL, or as high as is reasonably obtainable, is finely ground in a ball mill and then mixed with cooled recycled phosphoric acidgypsum slurry in a digestion tank (Figs. and ).At this stage the only reaction which occurs is between acid and any carbonates present in the rock, and between phosphates and low concentrations of sulfuric acid which may be

We offer phosphate processing solutions from ore to purified phosphoric acid (TAT) offers differentiated, projectspecific process technologies based upon decades of research, equipment design and project execution. Advanced solutions include Solvent TAT provides the full suite of technologies for the beneficiation of phosphate rock.

Phosphates Processing. With decades of experience in working with phosphates, we can assist you with all of your phosphate processing needs, whether youre working with granular fertilizers, animal feed, or other phosphate products.

rock phosphate crushing plant power consumption. the phosphate the industry in sa. phosphate rock beneficiation process. vendor or supplier of rock phosphate beneficiation process plant in india. increasing yield in phosphate rock beneficiation and chemical processing

WhatsApp)

WhatsApp)