how control residue of cement mill kiln

Raw Mill Residue High Pakistan. is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement.

WhatsApp)

WhatsApp)

Raw Mill Residue High Pakistan. is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement.

Raw Mill Residue For Cement Raw Grinding Machine Residue. Raw mill residue for cement grinding of cement in 4to 6 residue how to control raw mill business plan for raw mill residue for cement raw grinding machine residue Cement Process and More Info Raw Mill Residue High Pakistan Raw Mill Residue High Pakistan plant Cottons Journey Cotton is a plant it grows wild in many places on the earth.

Re: Cement mill Residue. Dear Mr Jatin, You have not mentioned circuit of your assume that it might be a closed circuit cement mill. Best possible way to reduce residue on 45micron is by increasing circulation factor across the other way is to decrese cut size of your dynamic separator by increasing cage rotor speed.

Raw mill residue for cementaw mill residue for cementain productse jaw crusherrawmill is the equipment used to grind raw materials into quot;rawmixquot; during the manufacture of cementy we check residue of raw mix cement only through 90 212 mic in raw mill also for cement mill through 45 micronead more.

A mio t/a cement plant is having a closed circuit ball mill for cement grinding: The mill has been operating with satisfactory performance interms of system availability and output, however power consumption was on higher side. System Description Mill Rated capacity 150 t/h OPC at

So the high mineralogical differences in raw material ground requires higher product fineness (as it is the safe requirement for mix type RM2) and the mill feed materials with like gridibility index may have the liberty to target a little higher residue.

Cement Process amp; Quality Control International Cement Review. Mineralogy of Raw Material used for manufacturing of Cement. 2. Why we check residue of Raw Mix amp; Cement only through 90 amp; 212 Mic in raw mill amp; also for...

cement mill residue Raw Mill Residue For Cement Raw Grinding Machine Residue. Cement mill Wikipedia. A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than

The strength development of concrete is the result of the chemical reaction of water with cement particles. The reaction always starts at the surface of the cement particles. Thus larger the surface available for reaction, greater is the rate of hydration and strength development.. Determination of cement fineness shall not be limited to only Blaine value or a sieve residue information on

cement mill residue Raw Mill Residue For Cement Raw Grinding Machine Residue. Cement mill Wikipedia. A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than

raw mill residue for cement. raw meal drying in cement process YouTube Feb 6 2014 raw meal drying in cement process More details materials are normally ground to finenesses between 10 and 15 residue on a 90 micron sieve to line cement raw mill plantSBM cement

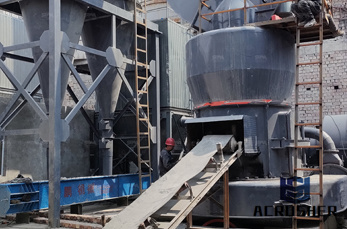

Raw mill is generally called cement raw mill, raw mill in cement plant, it refers to a common type of cement equipment in the cement the cement manufacturing process, raw mill in cement plant grind cement raw materials into the raw mix, and the raw mix is sent to the cement kiln to make cement clinker, next, clinker and other admixtures will be ground into finished cement by cement mill.

This paper mainly introduces the raw mill in cement plant. In order to achieve the desired setting qualities in the finished product, a quantity (28%, but typically 5%) of calcium sulfate (usually gypsum or anhydrite) is added to the clinker and the mixture is finely ground to form the finished cement powder. This is achieved in a cement raw mill.

From the early 1900s, both for cement grinding and for grinding hard raw materials, whether by wet or dry process, the standard arrangement was a ball mill for preliminary grinding (to below mm), followed by a tube mill for fine grinding.

Cement Plant Raw Mill Residue Samac. why use seive in raw mill residue how to control residue in ball mill in cement plant. how to control residue in ball mill in, or a sieve residue of the, time, and remote control of grinding pressure, 36,8 raw material OPC residue, mill .

Raw Mill Optimization Module The Raw Mill Optimization option controls both the temperature, the feed rate to the mill and the separator speed in order to achieve the required throughput for kiln. Where starting the mill requires dampers to be moved, to change gas flow paths, the module will also respond to these effects to keep the system stable.

Raw Mill Residue High. Raw mill residue for cement grinding trends in the cement industry cement mill high grade limestone raw mill iron ore alumina used tires get price and support online raw mill residue high pakistan cdsspgc raw mill residue high pakistan plant cottons journey cotton is a plant it grows wild in many places on the earth but

Ball Mill Ball mills with high efficiency separators have been used for raw material and cement grinding in cement plants all these years. Ball mill is a cylinder rotating at about 7080% of critical speed on two trunnions in white metal bearings or slide shoe bearings for large capacity mills.

Mono Chamber Raw Mill Ball Charge Design. Hi experts, I want to design a ball charge for a monochamber raw mill in a white cement plant and wanted to know your opinion about it. The raw material is preground by to a hammer crusher and after separation by a third generation separator the course material is fed to the monochamber raw mill.

The cement obtained gave a comprehensive strength of 2N/mr2. DEFINITION OF TERMS. OPC Ordinary Portland cement LSF Lime saturation factor Quicklime Calcium oxide Ca0 Raw meal Secondary raw material that is fed into the kiln for burning Raw mill A tube like machinery where the grinding of raw material takes place.

raw mill expert program in cement . Second Hand Concrete Batching Plants For Sale In Malaysia. Market of Second Hand Concrete Batching Plants For Sale In MalaysiaDevelopment of Second Hand Concrete Batching Plants are to largescale, automated, intelligen. Raw

raw mill residue for cement in china. CO 2 emissions are caused by cement plants, while 900 kg CO 2 is emitted to the atmosphere for producing one ton of cement. In this work, global strategies and potentials toward mitigation of CO 2 emissions in cement plant have been discussed and the most promising approaches have been introduced.

WhatsApp)

WhatsApp)