Grinding Machine: Types, Parts, Working amp; Operations (With

Grinding Machine: Types, Parts, Working amp; Operations (With

WhatsApp)

WhatsApp)

Grinding Machine: Types, Parts, Working amp; Operations (With

parts of stirred grinding machine [ 5275 Ratings ] The Gulin product line, consisting of more than 30 machines, sets the standard for our industry. We plan to help you meet your needs with our equipment, with our distribution and product support system, and the

High Chromium Wear Liner for Stirred Grinding Mill Machine Spares Parts, find complete details about High Chromium Wear Liner for Stirred Grinding Mill Machine Spares Parts, Stirred Grinding Mill Machine, Stirred Grinding Spare Parts, wear Liner Hyton Casting

#0183;#32;Machines in which grinding wheels are fitted and grinding is done, such machines are called grinding machines. On the basis of their function, they can be divided into two parts. Ordinary grinding machines which are widely used. These are called rough or snagging grinders. The following types of grinders are included in this category.

Grinding Machine Parts and Functions. 6) Wheel Head :It is the compartment that is moved vertically up or down using a traversing wheel called Vertical Feed Hand Wheel . We move this wheel head so that the grinding wheel can touch the workpiece. 7) Three types of traversing wheel :

For fine and ultrafine grinding, stirred mill and tower mill technology provides efficient solutions to meet your needs. These mills operate at power intensities that give you unrestricted customization options for a wide range of industries and grinding applications

Working principle of Grinding Machine: The working principle of a grinding machine is quite easier to understand.. In a grinding machine, there is an electric motor which supplies the motion power to the grinding wheel with the help of a belt and pulley.. So when we start the electric motor the motor rotates at a certain rpm ( RPM, it may change according to the types of grinding

Stirred milling VERTIMILL#174; grinding mill Components and features 9 Gear reducer Motor Ball port Feed chute Stirred milling Machine Design goals 24 13 Nov 2013 Lowest total cost of ownership Energy efficiency Grinding media consumption Wear and Parts

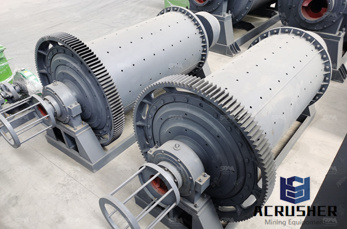

A grinding machine, often shortened to grinder, is one of power tools or machine tools used for grinding, it is a type of machining using an abrasive wheel as the cutting grain of abrasive on the wheel''s surface cuts a small chip from the workpiece via shear deformation.. Grinding is used to finish workpieces that must show high surface quality (, low surface roughness) and high

Parts Of Piston Ring Grinding Machine. Piston Ring Grinding Machines. Piston ring grinding machines are used for mass production of parts in the same manner as roller bearing grinding machinesigh performance and precision are two decisive aspects for the success of the effective piston ring grinding machines from the comprehensive diskus line of double side face grinding.

Stirred mills have been proven to provide energy savings when compared with traditional grinding mills. The finer the product required, the more efficient stirred mills will be. The attrition grinding action, vertical arrangement, and the finer media size distribution contribute to make stirred mills energy efficient grinding machines.

CNC grinding machines are hightech machine tools with a broad performance spectrum. Often CNC grinding machines do not work in an optimum operational range, the machines frequently consume an unnecessary amount of energy or coolant lubricant, thereby causing cycle times which are too high or (ir)regular grinding burn on the ground part.

Stirred Media Grinding Mills, Tower Mill, Fine Grinding Tower / Stirred Grinding Mills Tower mills, low speed vertical stirred mills, and high speed stirred mills are used for fine and ultra fine grinding.

Milling Machine Manuals UManuals Machinery Manuals amp; Parts Home Milling Machines... These machines move both the cutter MODEL G0755 Read Instruction Manual before Operating This Machine recommended for this machine by Grizzly. wet grinding mill in stirred media mills Crusher stone #187;tarren mill map instruction manuals

offers 18,803 parts of grinding machine products. About 8% of these are Grinding Machines, 12% are Grinding Equipment, and 5% are Flour Mill. A wide variety of parts of grinding machine options are available to you, such as condition, key selling points, and applicable industries.

Machines in which grinding wheels are fitted and grinding is done, such machines are called grinding machines. On the basis of their function, they can be divided into two parts. Ordinary grinding machines which are widely used. These are called rough or snagging grinders. The following types of grinders are included in this category.

WhatsApp)

WhatsApp)