Minerals and metals demand recovery in 2021

Dec 08, 2020#0183;#32;Miners and metal producers should see a more favourable pricing environment in 2021 as almost all mineral and metal prices (except iron ore) are

WhatsApp)

WhatsApp)

Dec 08, 2020#0183;#32;Miners and metal producers should see a more favourable pricing environment in 2021 as almost all mineral and metal prices (except iron ore) are

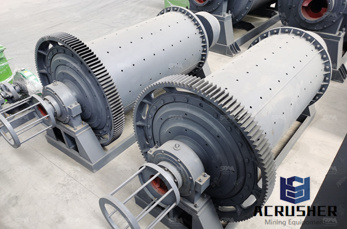

Metal Procesing Cost In Mining. Our company mainly producing and selling machines like jaw crusher, ball mill, sand maker, sand washing machine, mobile crushing plant, Metal Procesing Cost In rock industries nigeria plc ebonyi state Establishing a special research and development base and taking technological innovation as our main duty help us always taking the lead in the field

A small gold mine flowsheet is shown below together with cost data which clearly shows the results that can be obtained when handling a low grade ore by a simple process. There are many commendable features in such a set up and no complicated machines or practices are embodied in this plan. In fact, its simplicity is appealing and the results obtained prove the practicability of this

Compared to tin mining, the history of zinc mining is relatively short. In the 18th century, it was discovered that sphalerite, or zinc sulfide, could be smelted into brass, resulting in the first patented techniques. Since then, the zinc industry has progressed to the current zinc mining process and production methods used today.

Metal Procesing Cost In Mining abgeltungsteuer. Run of mine ore Definition Resource/Mining Dictionary Casey. The run of mine (ROM) ore refers to ore in its natural, unprocessed state just as it is ore has been extracted from the earth, the metal or other valuable materials it far as processing is concerned, size does matter: grinding costs more

metal procesing cost in mining; Customer Case. 200Th Granite Crushing Plant. The 200t/h granite crushing plant in Russia uses HPT220 hydraulic cone crusher as the core crushing equipment. Gold Ore Concentration Plant. Gold ore whose types of deposits are diverse and complex is the mineral assemblage of gold. With features of chalcophile

Lead mining, for example, ground to a halt due to the Black Death pandemic, when atmospheric lead pollution from smelting dropped to natural levels (zero) for the first and only time in the last 2000 years. The great demand of metals, for armour, could not

Mining and processing cost will swing up or down depending upon the production rate. In this example, the production rate is set to 5Mtpa (for the base case), then in creased to,

metal procesing cost in mining. metal procesing cost in mining. Mining the consequences of the rare earths industry GreenbizFeb 25, 2017#183; Rare earth metal mining operations and processing outside of China showed a shrinking bottom line as profit opportunities dried up when mining companies faced the option of selling at or near the prices.

Mining Cost Service is the industry standard reference for Mining Cost Estimation. This system places cost estimating data at your fingertips with conveniently indexed information to make your cost estimates faster, easier, and more credible. Monthly updates assure that you are working with the most current cost

The first set of factors relates to the actual costs of inputs: Skilled labor, mining materials, equipment, reagents, structural steel, and everything else that goes into running a mine. The second set of factors relate to the price of the underlying metalof the mine. higher metal prices encourage mining lower grade properties driving higher the cash cost curve the price of the metal also influences input costs.

A mining company is considering to spend 2 million on a leach processing procedure that can process 400 tonnes of copper per year with a recovery rate of 75 per cent at a cost 100 per ton.

Mar 09, 2020#0183;#32;Mining manganese nodules on the ocean floor is a great source of rare metals, but even though you dont generate toxic mine tailings like on land, there

Iron processing, use of a smelting process to turn the ore into a form from which products can be in this article also is a discussion of the mining of iron and of its preparation for smelting. Iron (Fe) is a relatively dense metal with a silvery white appearance and distinctive magnetic properties. It constitutes 5 percent by weight of the Earths crust, and it is the

Table of ContentsMILLINGPLANT AND DEVELOPMENTSTOPINGDISTRIBUTED ACCOUNTSList of Forms In the zeal for opening up new orebodies, or for extracting the ore from attractive bodies already opened up, we very often lose sight of the fact, that, after all, the operation of a mine is a business proposition, pure and simple, and, for the best workingresults, should be treated upon a strict

Aluminum, or aluminium (Al), is a silvery white metal with a melting point of 660 #176;C (1,220 #176;F) and a density of grams per cubic cm. The most abundant metallic element, it constitutes percent of Earths crust. In nature it occurs chemically combined with oxygen and other elements. In the pure state it is soft and ductile, but it can be alloyed with many other elements to increase

Material Processing and Mining Rates Guide The following is a guide for understanding the mathematics behind the processing and mining of materials. This is not a resource farming guide. I collected observable data over an extended period of time in an attempt to reconstruct what is going on behind the scenes.

GK Home gt; GK Blog gt; Tin Mining and Processing: Everything you Need to Know Over the course of mining history, great progress has been made in the way materials are extracted from the earth. Compact, heavyduty equipment has increased efficiency and costeffectiveness while helping to reduce waste and harmful chemicals.

Aug 21, 2020#0183;#32;Processing From Brine Much of the lithium produced today is extracted from brine reservoirs called salars that are located in highelevation areas of Bolivia, Argentina, and Chile. In order to extract lithium from brines, the saltrich waters must first be pumped to the surface into a series of large evaporation ponds where solar evaporation

Jun 23, 2013#0183;#32;Effective costs of Copper Processing As each tonne of ore produces t of copper inconcentrates, with a free market value of #163;, so totalproduction costs of copper in concentrates : However, if the ore contains appreciable byproducts, theeffective production costs are reduced. Assuming the concentrate contains 25 gpt of gold and 70gpt of silver, then The payment of gold, at

Mining Cost Service continues to be a useful reference on a wide range of topics for early stage mine planning through to fill the gaps on more detailed studies. Mining Cost Service provides an independent source for information on equipment, quantities and cost for a significant number of mining methods and range of production rates.

WhatsApp)

WhatsApp)