Cement Plants in India India Map, Map of India

26/08/2011#0183;#32;Andhra Pradesh has the maximum number of cement plants (20) and it contributes 17 million tonnes of cement to India. Rajasthan, Gujarat and Tamil Nadu have 16, 12

WhatsApp)

WhatsApp)

26/08/2011#0183;#32;Andhra Pradesh has the maximum number of cement plants (20) and it contributes 17 million tonnes of cement to India. Rajasthan, Gujarat and Tamil Nadu have 16, 12

full project of india cement. 53 Grade Cement Price list Buy Opc 53 Grade Cement in . Shop for 53 grade cement online at wholesale rates in Bangalore. Get today''''s price for 53 grade cement per bag. Multiple brands at best offer prices on materialtree . Free shipping and COD.

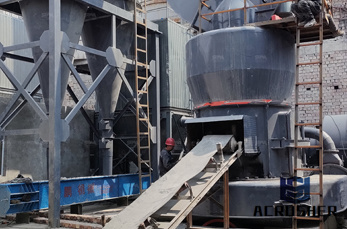

With an annual capacity of producing close to 11 million tonne cement, Wonder Cement is already among India''s largest cement producers. But strengthening that position required big changes.

03/06/2020#0183;#32;23 October 2020. India: Dalmia Bharat plans to build an integrated cement plant in Kalaburgi, Karnataka. BusinessLine Online News has reported that the plant will cost around US270m. The company already operates the /yr Belagavi plant in

Indian Cement Industry is the second largest cement producer in the world after China with a total capacity of Million Tonnes (MT). Government of India has been giving immense boost to various infrastructure projects, housing facilities and road networks, the cement industry in India is currently growing at an enviable pace.

The production of cement in India started in 1889 by company based in Kolkata. Full access: To this and over 1 Downloads allow integration with your project Valid data: Access to all

Cement Production in India increased to 24229 Thousands of Tonnes in September from 20850 Thousands of Tonnes in August of 2020. Cement Production in India averaged Thousands of Tonnes from 2004 until 2020, reaching an all time high of 33124 Thousands of Tonnes in March of 2019 and a record low of 4077 Thousands of Tonnes in April of 2020.

21/10/2020#0183;#32;India is the second largest producer of cement in the world. No wonder, India''s cement industry is a vital part of its economy, providing employment to more than a million people, directly or indirectly. Ever since it was deregulated in 1982, the Indian cement industry has attracted huge investments, both from Indian as well as foreign investors.

India Cements Ltd 1. The India Cements Ltd Chilamkur Works ANDHRA PRADESH 2. The India Cements Ltd Dalavoi TAMIL NADU 3. The India Cements Ltd Parli MARASHTRA 4. The India Cements Ltd Raasi Cement

Cement firms hike prices even as expansion plans come to a grinding halt. India Cements partially resumes operations at manufacturing facilities. Wonder Cement invests 450 cr in Marashtra clinker grinding unit ; Shree cement gets coal linkage for Batapara Plant; Udaipur Cement Works approves capex of Crore

India Cements Limited is a cement manufacturing company in India. The company is headed by former International Cricket Council chairman N. Srinivasan. It was established in 1946 by S. N. N. Sankaralinga Iyer and the first plant was set up at Thalaiyuthu in Tamil Nadu in 1949.

Local Websites HeidelbergCement India LimitedZuari Cement HeidelbergCement entered India in 2006 and has consistently pursued its strategy of growth in developing markets. The Group acquired majority stakes in Mysore Cements and Cochin Cements, as well as the Indorama Cement joint venture, which was converted to a full acquisition in 2008. Following the merger with Indorama Cement, Mysore

16/10/2020#0183;#32;In 2018, India was the second largest producer of cement in the world. The country had about eight percent of the global installed capacity that year. Consumption of cement at

Download fulltext PDF Read fulltext. The quality of Indian cement is at par with the best produced anywhere in the world. Today India is world''s second largest cement producing country, with

High Performance Concrete was introduced in India initially for the reconstruction of the prestressed concrete dome of the Kaiga Atomic Power Project, followed for parts of the Reactors at Tarapur and Rajasthan. Subsequently, a number of bridges and flyovers have introduced HPC up to M75 grade in different parts of India.

6. For all structural elements, M25 grade concrete will be used. However, higher M30 grade concrete is used for central columns up to plinth, in ground floor and in the first floor. 7. Sizes of all columns in upper floors are kept the same; however, for columns up to plinth, sizes are increased. 8. The floor diaphragms are assumed to be rigid. 9.

17/09/2017#0183;#32;It is the secondbest cement brand, founded in 1979 (Bewar in the Ajmer district of Rajasthan), with the production capacity of Million Tonnes Per Annum (MTA).It has a total of 8 cement manufacturing plants and more than 5411 employees in its abode. The headquarter is in Kolkata, India, while the Ramp;D centre is located in Bewar and Ras, Uttar Pradesh.

Cement. Status: Delayed/PutonHold Promoter: Bhavya Cements Project: Delayed an expansion of a cement grinding unit amp; captive power plant Location: Village Thangeda, dist. Guntur, Andhra Pradesh Project Details: The capacity of the cement plant was to be augmented from MTPA to 4 MTPA under 2 phases on existing land. Environmental clearance is yet to be received.

WhatsApp)

WhatsApp)