Iron Ore News Iron Ore Mining, Investment, Price News

Iron Ore mining, investment and price news from The latest news on iron ore mines and properties, mining companies and iron ore prices.

WhatsApp)

WhatsApp)

Iron Ore mining, investment and price news from The latest news on iron ore mines and properties, mining companies and iron ore prices.

14/03/2014#0183;#32;Drilling in the benches of open pit mining is done for production of iron ore with mechanized drills specific for each mining method. The main objective of drilling operations is to create a hole of suitable diameter, depth and direction in rock for explosives to be placed for blasting activities.

Mining of Iron Ores IspatGuru

Over time, the bonus ore provided from the armour will boost iron ore and Mining experience output, so it is recommended to wear the armour if players can meet the low minimum skill requirements for completing the tasks. Players with higher Mining levels can also occasionally opt to mine the nearby coal, but bear in mind that the time they take to mine might yield less profit per hour than just sticking to iron.

19/10/2020#0183;#32;Australian gold mining company MACA has secured a A185m (131m) mining and crushing contract for the resource exploration company Fenix Resources Iron Ridge iron ore project in Western Australia (WA). The Iron Ridge project is an openpit iron ore project located in

Antique iron ore mining equipment, Minas de Alquife, Andalusia, Spain wide horizontal panorama of open pit iron ore mine in South Australia Iron Knob town. wide horizontal panorama of open pit iron ore mine in South Australia Iron Knob town. https:// https://

Electricpowered, remotecontrolled drilling and ore handling equipment supplied by and Tamrock is widely used. After blasting, loadhauldump machines (some of which are fully automated) carry the runofmine ore to the nearest ore pass, from which it is loaded automatically on to one of the trains operating on the 1,045m level.

Jinpeng Mining Machinery is a hightechnological enterprise that integrates research, design, manufacture, installation and commissioning, personal training, aftersales service etc, depending on the advanced equipments and abundant technological strength, we could offer onestop service and ensure the high rate recovery of clients'' mine.

06/11/2020#0183;#32;Rural Minnesota counties hope the use of a byproduct from the states iron ore mining industry could provide a lowercost way to make dangerous curves

12/10/2020#0183;#32;Iron Ore Pelletizing Equipment Application Abstract The Iron Ore Pelletizing Equipment is commonly used into: Mining Metallurgy Construction Others

Reliable equipment to handle the large volumes required in your iron ore mine. For the large volumes of iron ore you produce every day, you need proven and reliable equipment to sustain or increase your production level and avoid unplanned stops. Automation, digitalization and use of the latest technology in everything from bulk materials handling stockyard machines to crushers,

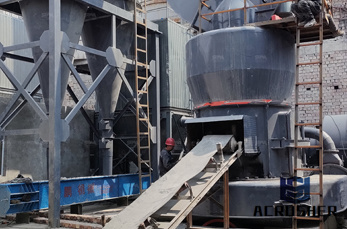

Iron Ore Mining Equipment. Beneficiation process of the three most critical process: Crushing process, Milling process, Screening process and Flotation process. We are one of the leading manufacturer and exporter of Mineral Ore Beneficiation Plant and Machines, fabricated from superior quality of raw materials. Stone Crusher For Sale View More #187;.

01/11/2020#0183;#32;A new iron ore mine is set to emerge in the Pilbara region of Western Australia after junior miner Strike Resources completed a feasibility study (FS) for the Paulsens East project.

Equipment list for iron ore Mining, List of equipments utilised in iron ore mining Mining Wikipedia the free encyclopedia Mining is the extraction of valuable minerals or other geological materials from the earth from an orebody lode vein #187; More Mining Wikipedia the free encyclopedia Mining is

Smelting involves heating up ore until the metal becomes spongy and the chemical compounds in the ore begin to break down. Most important, it releases oxygen from the iron ore, which makes up a high percentage of common iron ores. The most primitive facility used to smelt iron is a bloomery. There, a blacksmith burns charcoal with iron ore and a good supply of oxygen (provided by a bellows or blower).

Summary: The runofmine ore processing consists of crushing and wet screening to reduce the ore to 6 mm size. Gravity separation methods, employing jigs, spirals and hydroclassifiers, are utilized to upgrade coarse fractions. Materials below mm are separated

WhatsApp)

WhatsApp)