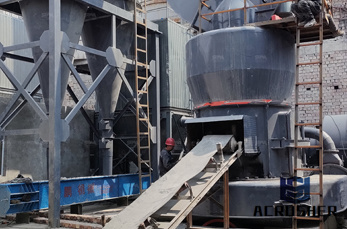

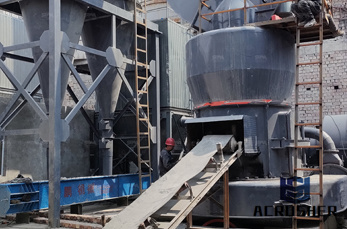

3D Animation Demo amp; working site of Ball Mill YouTube

Nov 13, 2014#0183;#32;Offical website: website: webpage:

WhatsApp)

WhatsApp)

Nov 13, 2014#0183;#32;Offical website: website: webpage:

Metallurgical ContentBall Mill Capacity VS Rod Mill CapacityWorking Principle amp; OperationRod Mill Capacity TableBall VS Rod Mill ConversionTypes of Mill DischargeBall Mill Trunnion and Mill Grate DischargePeripheral Grinding Mill DischargeLoad Capacity of Trunnion BearingsBall Mill amp; Rod Mill LinersGrinding Mill GearsGrinding Mill DrivesBall Mill Grinding CircuitBall Mill SpecificationsAll

grinding homemade airfloat charcoal. The best way to tell if your mill is properly charge is to listen to it after about 15 minutes of grinding. You should hear a continuous cascading sound that is fairly loud. If the mill seems quiet or muffled, you are probably

Sepors 16 x 32 continuous ball or rod mill is ideal for pilot plant studies of ore grinding and processing or just regular small scale grinding requirements you may have. The mill can be used in a closed circuit, with a spiral classifier, screen or cyclones or as a single pass grinding mill.

This project is to design and fabricate the mini ball mill that can grind the solid state of various type of materials into nanopowder. The cylindrical jar is used as a mill that would rotate the

Ball Mill Design/Power Calculation. The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum chunk size, product size as P80 and maximum and

Continuous Dry Grinding Ball Mill With High Alumina Liner. continuous dry grinding ball mill are mainly grid ball millsAccording to different materials size you can choose the ball mill of proper length and diameter ratiothe end product can be controlled by separatorIn the internal of dry type ball millthere is ventilating device to increase the mobility of input materialsZoneding Machine dry

desing a continuous ball mill. batch ball mill and continuous ball mill with different grinding media and different design depend on the nature of Contact Us. 1849. In its very first year of operation, the Chamber pressed for the provision of information and communications infrastructure reliable mail. continuous ball mill design desing a continuous ball mill

In one of them I have to design a ball mill, and we have to use a 3m long cylinder of 2m diameter. This process is going to be a discontinous process, that means the mill have to be charged with the balls and materials and then after some time it stops and you have to take out the materials and the balls.

The Continuous Ball Mill. We are a leading ball mill manufacturer, exporter when it comes to continuous ball mills. Our commitment to quality is the main reason why we deliver worldclass continuous ball mills. Our stainless steel ball mills are used to grind ores and minerals from a feed size of 6mm and Moh''s hardness upto 5 to d97lt;6um.

A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls; mounted on a metallic frame such that it can be rotated along its longitudinal axis. The balls which could be of different diameter occupy 30 50 % of the mill volume and its size depends on the feed and mill size.

The vertical ball mill is used for the processing of highviscous premixed pastes, like chocolate, compound, cr#232;mes, nut and seedpaste. The continuous design vertical ball mill can be used in a 1 3 stage refining system, with 1 3 ball mills in a sequential row after the premixer.

The Continuous Ball and Pebble Mill grinding units range from 24quot; (610 mm) diameter to 96quot; (2438 mm) diameter and from 36quot; (915 mm) long to 36''0quot; (11 m) long. PATTERSON''s unmatched Ball and Pebble Mill custom design experience and manufacturing capability is your assurance of a system that meets your requirement for maximum grinding efficiency at a costeffective price.

In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rob mill amp; ball mills, the ore in order to liberate the minerals. In the chemical and process industries, grinding is an important step in preparing raw materials for subsequent treatment. In present day practice, ore is

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum chunk size, product size as P80 and maximum and finally the type of circuit open/closed

continuous ball mill design . Second Hand Concrete Batching Plants For Sale In Malaysia. Market of Second Hand Concrete Batching Plants For Sale In MalaysiaDevelopment of Second Hand Concrete Batching Plants are to largescale, automated, intelligen. Raw Complex Gold Ore Processing Machine.

Ball Mill Operating Principles Components Uses . Basic principle of ec ball mill machine the high energy ball mill e max and mm were developed for grinding with the highest energy input the innovative design of both the mills and the grinding jars allows for continuous grinding down to the nano range in the shortest amount of time.

A ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering. It works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell. A ball mill consists of a hollow cylindrical shell rotating about its axis. The axis of the shell may be either

continuous ball mill design classifier reduce wear in singapore. Ball Mill Ball mill is a key piece of equipment for grinding crushed Mill is used to grind materials into extremely fine powder mainly for use in mineral precessing mill can be used in open circuit or in closed circuit with screenspiral classifier or hydrocyclone to achieve certain discharging size...We are a professional mining

Nov 29, 2018#0183;#32;The Continuous Ball Mill is a type of grinder used to grind and blend materials. It works on the principle of impact and attrition. For more information: htt...

WhatsApp)

WhatsApp)