Mill Critical Speed Calculation

The mill was rotated at 50, 62, 75 and 90% of the critical speed. Six lifter bars of rectangular crosssection were used at equal spacing. The overall motion of the balls

WhatsApp)

WhatsApp)

The mill was rotated at 50, 62, 75 and 90% of the critical speed. Six lifter bars of rectangular crosssection were used at equal spacing. The overall motion of the balls

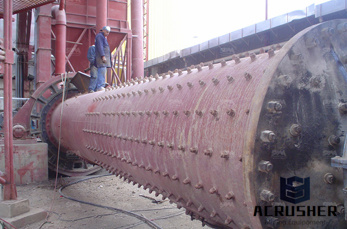

The ball mill consists of a metal cylinder and a ball. The working principle is that when the cylinder is rotated, the grinding body (ball) and the object to be polished (material) installed in the cylinder are rotated by the cylinder under the action of friction and centrifugal force.

#0183;#32;Deals with two most important topics of Food Engineering namely ball mill and sphericity. Speed, Torque and Horsepower Duration: (India) Ltd. 41,877 views. 11:36.

critical speed of ball mill calculation india. critical speed of ball mill ball mill critical speed ball mill efficiencyball mill media as a professional intermittence ball mill product drum dryer manufacturer bailing machinery analyzes the factors affecting the production efficiency looking to produce help and support to customers with respect of rotating speed

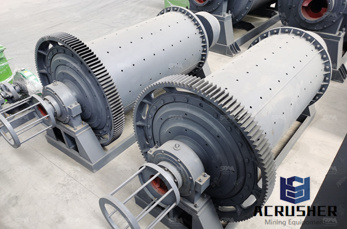

Most ball mills operate most efficiently between 65% and 75% of their critical speed. Photo of a 10 Ft diameter by 32 Ft long ball mill in a Cement Plant. Photo of a series of ball mills in a Copper Plant, grinding the ore for flotation.

Equation formula critical speed of the ball mill calculation backup: the formula used for critical speed is: n c 766(d05) wheren c is the critical speed,in revolutions per minute,get price critical speed equation of a ball mill ball mills mine engineercominformation on ball mills .If you want to learn about our products, please call or write mail consultation.

critical speed calculation of ball mill ZCRUSHER Critical Speed Of Ball Mill Calculation India TECHNICAL NOTES 8 GRINDING R. P. King. The critical speed of the mill, amp; c, is defined as the Figure Simplified Chat Now; critical speed ball mill calculation Critical Speed Of Ball Mill Calculation India. TECHNICAL NOTES 8 GRINDING R. P

Chapter 7. Tubular Ball Mills Scribd of the critical speed and a ball charge of 3545% of the mill Mill length, % charge or ball loading, Mill speed, Mill type. An approximate mill power calculation

Oleg D. Neikov, in Handbook of NonFerrous Metal Powders, 2009. Tumbling Ball Mills. Tumbling ball mills or ball mills are most widely used in both wet and dry systems, in batch and continuous operations, and on a small and large scale.. Grinding elements in ball mills travel at different velocities. Therefore, collision force, direction and kinetic energy between two or more elements vary

The mill critical speed will be calculated based on the diameter (above) less twice this shell liner width. Mill Actual RPM: Enter the measured mill rotation in revolutions per minute.

#0183;#32;Types of GRINDER IN HINDI, Hammer mill, Ball mill amp; Critical speed of Ball mill ~~~~~~~~~Please watch: quot;Introduced quot; Crushers

A Ball Mill Critical Speed (actually ball, rod, AG or SAG) is the speed at which the centrifugal forces equal gravitational forces at the mill shells inside surface and no balls will fall from its position onto the shell. The imagery below helps explain what goes on inside a mill as speed varies. Use our online formula The mill speed is typically defined as the percent of the Theoretical

The critical speed of ball mill is given by, where R = radius of ball mill; r = radius of ball. For R = 1000 mm and r = 50 mm, n c = rpm. But the mill is operated at a speed of 15 rpm. Therefore, the mill is operated at 100 x 15/ = % of critical speed.

Mill Speed Critical Speed. Mill Speed . No matter how large or small a mill, ball mill, ceramic lined mill, pebble mill, jar mill or laboratory jar rolling mill, its rotational speed is important to proper and efficient mill operation. Too low a speed and little energy is imparted on the product.

Critical Speed Calculation For Ball Mill. Mar 20, 2019 equation for critical speed of a ball mill equation for critical speed of a ball mill GunpowderWikipedia. Gunpowder, also known as black powder to distinguish it from modern smokeless gunpowder, is the earliest known chemical explosive. Get Price; Ball Mills

This page is about critical speed calculation formula of ball mill in madras tamil nadu india, click here to get more infomation about critical speed calculation formula of ball mill in madras tamil nadu india.

The critical speed of the mill, amp; c, is defined as the speed at which a single ball will just remain against the wall for a full cycle. At the top of the cycle =0 and Fc Fg () mp amp; 2 cDm 2 mpg () amp; c 2g Dm 1/2 () The critical speed is usually expressed in terms of the number of revolutions per second Nc amp; c 2 1 2 2g Dm 1/2 (2#215;)1/2

ball mill critical speed calculation. critical speed of ball mill calculation pdf SBM Machine. Mill Speed Critical Speed Paul O. Abb#233; . No matter how large or small a mill, ball mill,

In most cases, the ideal mill speed will have the media tumbling from the top of the pile (the shoulder) to the bottom (the toe) with many impacts along the way. The ideal mill speed is usually somewhere between 55% to 75% of critical speed. Critical Mill Speed. Critical Speed (left) is the speed at which the outer layer of media centrifuges against the wall. Second Critical Speed (middle) is the speed at which

critical speed ball mill calculation . Second Hand Concrete Batching Plants For Sale In Malaysia. Supplier of Outlook Of Indian MSand Production PlantSupplier of Outlook Of Indian MSand Production Plant as a pillar of the national economy in recent years i. Modification And Change In Ball Mill.

WhatsApp)

WhatsApp)