Hardinge Conical Regrind Mill YouTube

#0183;#32;For the Love of Physics Walter Lewin May 16, 2011 Duration: 1:01:26. Lectures by Walter Lewin. They will make you Physics. Recommended for you

WhatsApp)

WhatsApp)

#0183;#32;For the Love of Physics Walter Lewin May 16, 2011 Duration: 1:01:26. Lectures by Walter Lewin. They will make you Physics. Recommended for you

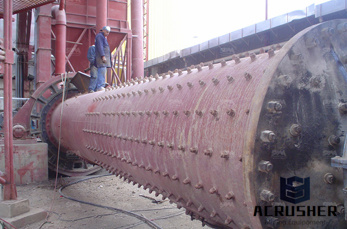

Conical Ball Mills Benefits amp; Advantages: Hardinge. Metallurgical ContentWorking Theory of the Hardinge Conical Ball MillWORKING PRINCIPLE inside the Hardinge BALL MILLConical Type VS Compartment Type Ball MillsHardinge Conical Ball Mill Replacement Liners The generally recognized fact that for economic reduction of any material, it is desirable to perform such reduction in steps or

Conical Ball Mill Crusher Long Arm Mining Equipmen. Processing capacity:110410t/h Feeding size:15mm Appliable Materials: silicate,ore dressing of ferrous metal,glass ceramics,iron ore,glass,ceramics grindable materials, various metal ores, nonmetallic ores, nonflammable and explosive materials

Conical Chamfer Cutters were developed to mill edge breaks and full chamfers, but also function well for replacing expensive hand deburring operations. Two primary designs were created to

Jump to navigation Jump to search. A conical mill (or conical screen mill) is a machine used to reduce the size of material in a uniform manner. It is an alternative to the hammermill or other forms of grinding mills. As the name implies, the conical mill varies in diameter

The ball mill is a hollow drum closed with loading and unloading end caps, filled with grinding media and rotated around its drum of the ball mill (Pic. 1) is a hollow cylinder of steel, lined inside with armor lining plates which protect it from impact and friction effects of the balls and the grinding material.

#0183;#32;Production line: Ball Mill Super Orion SO with a highperformance air classifier Turboplex ATP. Designed, engineered and manufactured by Hosokawa Alpine Augs...

The Hardinge Ball Mill consists of three sections. After the usual type of trunnion bearing the mill consists of a short conical section showing a sharp drop from feed entrance to maximum mill radius. A cylindrical section of varying length then follows and toward the discharge end connects with a comparatively long and conical section sloping, at considerably less pitch than at the feed end

FEATURES AISI 304L amp; 316L options available ATEX models available Explosion Containment (EPSR 11) versions Easy access for cleaning and routine adjustment via gentle, gas strut assisted, swing down cone cradle Fully interlocked with timedelay function for operator safety Customengineered versions to suit individual layout/process requirements Various grinding media and drive arrangements

The equations proposed previously by Austin, which allow for the presence of conical end sections on a cylindrical mill, have been applied to data on Hardinge conical ball mills ranging from m in diameter to m in diameter.

Ball Mills are generally used to grind material 1/4 inch and finer, down to the particle size of 20 to 75 microns. To achieve a reasonable efficiency with ball mills, they must be operated in a closed system, with oversize material continuously being recirculated back into the mill to be reduced.

The generally recognized fact that for economic reduction of any material, it is desirable to perform such reduction in steps or stages, removing that material which is sufficiently fine as soon as it is reduced and grinding it still finer in some device more adaptable to this finer reduction. It has been found that by so doing, the efficiency of the grinding machinery is increased, since

function of trunnion in ball mill oalebakkershoes. Ball mill 1456 of continuous operation for dry material grinding Ball mill 1456 is designed for dry grinding of ore and nonmetallic raw materials, Screw is inserted in the charging cover trunnion cavity and connected to trunnion ends by pins through the flange. protection and control functions; Get Price

Conical Ball Mill Operating Principle From Egypt. We are a professional mining machinery manufacturer, the main equipment including: jaw crusher, cone crusher and other sandstone equipment;Ball mill, flotation machine, concentrator and other beneficiation equipment; Powder Grinding Plant, rotary dryer, briquette machine, mining, metallurgy and other related you are interested in

Conical Ball Mills Benefits amp; Advantages: Hardinge

The Comil #174; comprises a vertically mounted rotating impeller which moves material across a mill screen causing a low velocity cutting action on the particle. If the particle is the right size it will pass through the screen, if not it remains in the cutting chamber until it reaches the desired size.

#0183;#32;CONCLUSIONS The following equations based on a mixture of theoretical reasoning and experimental observation are suggested for conical ball mills: Dry grinding m (shaft) '' 3LJ()pb~ (1~i~~ )(1+ )(1+f3), kW p c 29c pb for D,L in meters and Pb in metric tonsjm3, where lt; J lt; The ball load in the mill as a function of J is given by where The same ball load

A ball mill is a type of grinder used to grind and blend bulk material into QDs /nanosize using different sized balls. The working principle is simple; impact and attrition size reduction take place as the ball drops from near the top of a rotating hollow cylindrical shell.

WhatsApp)

WhatsApp)