Coal Milling In Thermal Power Plant Implementation

coal pulverization in coal mill of thermal power plants A typical coalfired thermal power plant. Coal is saving potential in thermal power plant amp; effective implementation of EC Act 2001 Milling

WhatsApp)

WhatsApp)

coal pulverization in coal mill of thermal power plants A typical coalfired thermal power plant. Coal is saving potential in thermal power plant amp; effective implementation of EC Act 2001 Milling

Coal Mill an overview ScienceDirect Topics. UltraGen II is the second of three demonstration plants proposed to advance coal power generation technology with 90% CO 2 capture to achieve thermal efficiencies comparable to those of todays stateoftheart coal power plants without capture. 3 It would incorporate nickelbased alloys in the steam system to allow temperatures of up to 700 #176;C

#0183;#32;coal mill/pulverizer in thermal power plants shivaji choudhury 2. Coal continues to play a predominant role in the production of electricity in the world, A very large percentage of the total coal is burned in pulverized form. Pulverized coal achieved its first commercial success in

Coal Storage system in Thermal Power Plants Posted by Tech Speak Blogger in Company On October 25, 2016. By H Ramakrishna. As coal is the primary fuel for a thermal power plant, adequate emphasis needs to be given for its proper handling and can be storedeither in open stockpiles or in covered stockpiles.

Coal mill pulverizer in thermal power plants. Nov 17, 2012#183; coal mill/pulverizer in thermal power plants shivaji choudhury 2. Coal continues to play a predominant role in the production of electricity in the world, A very large percentage of the total coal is burned in pulverized form.

coal milling in thermal power plant implementationImproving the Efficiency of Power Plants Firing HighMoisture Coal Mar 16, 2015 Implementation of onsi

Boiler accessories are the components which are installed to increase the efficiency of the steam power plant. The following accessories are given below: Air Preheater, Economiser, Superheater, Feed Pump, Injector. RELATED SEARCHES: Introduction of thermal power plant, Working of coal handling plant, Working of ash handling plant

Milling Process Of Coal Edeka Coal milling in thermal power plant implementation. Coal milling in thermal power plant implementation we are a largescale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment milling equipment mineral processing equipment and building ma.

Mar 04 2012 #183; In a coal based thermal power plant the initial process in the power generation is Coal Handling So in this article i will discuss the overall processes carried out at a Coal Handling plant in a coal based thermal power generating station The huge amount of coal is usually supplied through railways...We are a professional mining machinery manufacturer, the main equipment

The main raw material in a thermal power plant is steam coal. This type of coal is majorly imported from other countries. Seaport act as mediator in receiving cargo and send it to the receiver thermal power plant through wagons and tipper. Ma...

coal milling in thermal power plant implementationImproving the Efficiency of Power Plants Firing HighMoisture Coal Mar 16, 2015 Implementation of onsi

Lipinski The practical use of selected models of power plant Thermal power unit models. 3. Model of a The practical use of ringball coal mill model signals have fast time of reaction (counting process in power plant.

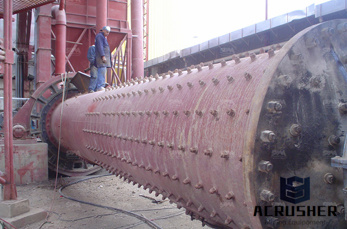

Coal milling in thermal power plant. PULVERIZING PLANT COAL MILL In modern thermal power generation plants in order to achieve maximum burning efficiency coal is pulverized or ground in order to mix it with the hot air and then feeding to furnace in a stream of hot air This helps increasing the surface area of the coal to action of oxygen and

WhatsApp)

WhatsApp)