Gold Processing Mill YouTube

#0183;#32;Vetran miner Mike Reynolds takes us through a tour of a gold processing mill that he has been working on for several years. He explains the process of taking...

WhatsApp)

WhatsApp)

#0183;#32;Vetran miner Mike Reynolds takes us through a tour of a gold processing mill that he has been working on for several years. He explains the process of taking...

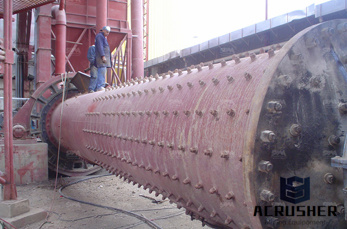

Ball Mill Cylinders. Mill cylinders are typically supplied with a cooling jacket on their cylindrical portion for temperature control, especially when processing temperaturesensitive materials. For extreme temperatures, the ends of the cylinder can also be furnished with cooling apparatus. View a Reverse Engineered Patterson Ball Mill Cylinder

Learn how a ball mill works, all of its main parts and some of its design features! This 3D animated video allows you to see all the internal parts of a ball...

canada gold rock ball mill, jaw ball mill rock crusher plant gold ore mining. small gold mining ball mill for process hard rock in south ore impact flail processing rock quartz crush mill gold. they will also process the gold bearing quartz rock much faster that a ball roller mill. our customers are located in south america, canada.

Ball mill Wikipedia. At the Gold ore Processing Plant gold should be The iron occur in Femineral ores contains impurities of BROWSE BY APPLICATION Build an endtoend solution that fits your application work processed and business needs Quarrying Ore mineral

Ball Mill Processing Gold Canada. Milling Equipment: ball mill processing gold canada A class of machinery and equipment that can be used to meet the production requirements of coarse grinding, fine grinding and super fine grinding in the field of industrial finished product can be controlled freely from 0 to 3000 mesh. We Are Here For Your Questions Anytime 24/7, Welcome Your

Ball Mill: Gold Processing Equipment, Star Trace offers turnkey solutions for gold processing plants. We are one of the leading project suppliers for gold plants and we work closely with our customers to fulfil their specific needs.

Gold Stryker#174; GS7000LD is a very large flail impact rock crusher gold mill that is very portable and perfect for the small gold mining operation. The Gold Stryker#174; GS7000LDuses a large 25 HP Honda Industrial engine for many years of trouble free use. It can process and crush up to 7 tons in a day, all the way down to #300 mesh through the mill to release the gold. 15999 Sale

Several types of ball mills exist. They differ to an extent in their operating principle. They also differ in their maximum capacity of the milling vessel, ranging from liters for planetary ball mills, mixer mills, or vibration ball mills to several 100 liters for horizontal rolling ball mills.

In most cases, gold processing with cyanide leaching, (SAG) mill and ball mill. The latter is preferred for wet sticky ores to minimise transfer point chute blockages, and can offer savings in both capital costs and longterm operating and maintenance costs. However,

In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rob mill amp; ball mills, the ore in order to liberate the minerals. In the chemical and process industries, grinding is an important step in preparing raw materials for subsequent treatment. In present day practice, ore is

The West Zone at Brucejack holds 600,000 oz. gold and 26 million oz. silver, hosted in million tonnes grading g/t gold and 279 g/t silver. The high grade nature of the ore has led to one challenge in the mill: When the rock hits the SAG and ball mills, coarse visible gold is freed.

BOLIDENALLIS CHALMERS X SAG Mill, X EGL Wet Overflow Regrind Ball Mill, 10,000 TPD Gold Plant w/SAG amp; Ball Mills, Gyratory amp; Cone Crushers, Rock Breakers amp; More, UNUSED ANI MINERAL PROCESSING '' x 43'' Ball Mill 13,400 HP, UNUSED 22'' x 38'' Ball Mills and 36'' x '' SAG Mill. Read the rest gt;

Industrial Ball Mills use horizontal rotating cylinders that contain the grinding media and the particles to be broken. The mass moves up the wall of the cylinder as it rotates and falls back into the toe of the mill when the force of gravity exceeds friction and centrifugal forces.

Below is the writeup of how a ball mill works, is used to crush ore and an explanation regarding its effectiveness in gold mining. The Purpose of Milling First of all, in order to get the best out of how this particular equipment is used it is important to get acquainted with knowledge on what it is, and is made of.

DOVE offers a wide range of Ball Mills applicable for wet or dry grinding operations, for grinding and regrinding stages of material processing. Wide range of capacities DOVE offers variety of models with a wide range of capacities, applicable for laboratories (200 gr.

#0183;#32;Ball Mills Capacity From T/H AdvantagesDesigned for long service life, minimum maintenance, can grind and homogenize mineral ores down to the nano range, large volume of processing capacity Max Feeding size lt;25mm Discharge Typesoverflow ball mills, grate discharge ball mills Service 24hrs quotation, custom made parts, processing

Ball Mills Capacity From T/H AdvantagesDesigned for long service life, minimum maintenance, can grind and homogenize mineral ores down to the nano range, large volume of processing capacity Max Feeding size lt;25mm Discharge Typesoverflow ball mills, grate discharge ball mills Service 24hrs quotation, custom made parts, processing

WhatsApp)

WhatsApp)