Types of Ball Mill Machine Meet Your Industrial Grinding

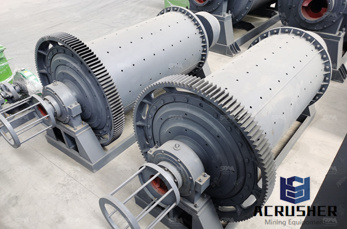

Choose a suitable ball mill machine for your industrial grinding line. As ball mill machine manufacturers, we also provide project solutions.

WhatsApp)

WhatsApp)

Choose a suitable ball mill machine for your industrial grinding line. As ball mill machine manufacturers, we also provide project solutions.

They do not provide the milling internal dynamics and therefore, the changes in charge motion due to operating parameters. There is no data related to liner design such as the toe and shoulder regions. Production is disrupted for the duration of the procedure: grindout, mill stoppage, mill startup and the transition period to steady state. Stresses, generated in the ball charge, increase

chrome grinding ball mill equipment mashin. Efficient Thickener. Efficient Thickener. Hydraulic Motor Driving Center Thickener. Hydraulic Motor Driving Center Thickener. Grid Type Ball Mill. Grid Type Ball Mill. Submerged Slurry Pump. Submerged Slurry Pump. Agitation Tank For Chemical Reagent. Agitation Tank For Chemical Reagent . High Frequency Dewatering Screen. High Frequency Dewatering

Ball mill internal Measure m diameter x 6 mt length external Measure mt x mt. Two access doors; Two inspection ports; complete and reinforced Bearings lateral reinforcements approximate weight of 21 ton steel smooth internal: Photos and images sent by email will be considered as ad authorization on our websites and marketing. Camargo Industrial has no responsability for the data

Description. GTEK Attritor Mill or Stirred Ball Mill is a grinding mill containing internally agitated media. It is a simple and effective method of grinding and dispersing fine and homogenous material quickly and repeatedly.. GTEK laboratory size Attritor Mill or Stirred Ball Mill is designed with variable speed drive for different RPM selections. The Attritor Ball Mill can operate with wet

Ball Mill. A Ball Mill a type of grinder is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paints. Ball Mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium.

For instance, we are able to import ball mill productionspray drier productionpolishing line production associated with our daily routine and etc. We will also provide technical services such as the installation of the equipment, maintenance of the equipment to our clients.

Inventory ID: 6CHM01. 3 Units UNUSED FL 26 x 43'' Dual Pinion Ball Mill with 2 ABB 9,000 kW (12,069 HP) Motors w/ ABB VFD for Total Power of 18,000 kW (24,138 HP)

New and Used Processing Mills insights. There are 49 Processing Mills for sale in Australia from which to choose. Overall 80% of Processing Mills buyers enquire on only used listings, 20% on new and % on both new and used Processing Mills usually enquire on different Processing Mills classifieds before organising finance for Processing Mills.

Mill (Grinder) Planetary Ball Mill 4x100ml GearDrive NEW. Mill, (Grinder), Planetary Ball Mill 4x100ml GearDrive NEW PQN04 series planetary ball mill s may be used for mixing, homogenizing, fine grinding, mechanical alloying, cell disruption, small volume hightec...

ball mill internal parts Stone Crushing Equipment. ball mill internal parts Stone Crushing Equipment . The building aggregates equipment of Aamp;C includes not only a series of single equipment of coarse crushing, intermediate and fine crushing, sand making and shaping, but also a batch of standardized design products of production line on the basis of many years of experience.

Ball mill external appearance and internal view. Ball mills are filled up to 40% with steel balls (with 3080 mm diameter), which effectively grind the ore. Fundamentals of mechanical alloying processes in ball mills. A ball mill is a relatively simple apparatus in . Chat Online. Ball Mill Equipment Equations. Ball Mill Equipment Equations Principle Ball mill mill grinding manufactured

Jun 20, 2019#0183;#32;Learn how a ball mill works, all of its main parts and some of its design features! This 3D animated video allows you to see all the internal parts of a ball...

Industrial Ball Mills use horizontal rotating cylinders that contain the grinding media and the particles to be broken. The mass moves up the wall of the cylinder as it rotates and falls back into the toe of the mill when the force of gravity exceeds friction and centrifugal forces. Particles are broken in the toe of the mill when caught in the collisions between the grinding media

A ball mill is a grinding machine used to grind, blend, and sometimes for mixing of materials for use in geology, ceramics, metallurgy, electronics, pharmacy, construction material, and light industry, etc. Ball mills are classified as attritor, planetary ball mill, high energy ball mill, horizontal ball mill, or shaker mill. The working principle is simple; impact and attrition size reduction

Coin cell equipment mainly include the small mixer device for slurry, manual film coating machine, electrode cutter, electrode press machine and crimping machine for coin cell sealing. All the equipment suitable for all kinds of coin cells, such as CR2016, CR2025, CR2032, CR2430 and so on. Coin cell research is the most convenient way for powder materials analysis.

WhatsApp)

WhatsApp)