ball mill calculation pdf and classifying production line

Define and calculate the classification system efficiency of a ball mill ball mill calculation pdf and classifying production line of alumina 10000 t y 27 Division, mirpur12, pallbi.

WhatsApp)

WhatsApp)

Define and calculate the classification system efficiency of a ball mill ball mill calculation pdf and classifying production line of alumina 10000 t y 27 Division, mirpur12, pallbi.

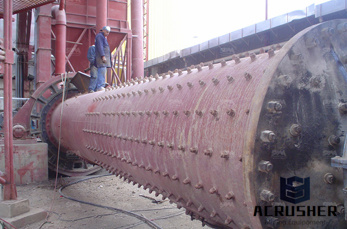

Classifying and Ball Mill Production Line. Vertical Classifying and Ball Mill gear ring and classifying wheel are made of ceramic such as aluminum oxide, zirconium oxide or silicon carbide, ensuring noncontact with metal throughout the grinding for high purity of the final product. 5 sets of Air Classifying Mill Production Line Details

Ball Mill Grinder Line Diagram, process flow of superfine ball mill ball mill and classifying production line of alumina 10000 t y, on line ball... Get Price. LOAN DOCUMENT H A N D L E Ball Mill Classifying Production Line. Be different from traditional ball mill

ALPAs ball mill classifying production line, ball mill and classifier work well together, can complement each other, high efficiency, large output, stable operation and stable product quality. Process

CR Superfine impact mill. CR Superfine impact mill is developed and optimized based on the similar domestic and foreign products with our practical experience, the multifunction equipment is very suitable for grinding, classifying, shaping and depolymerizing the materials with Mohs hardness below 4 degree.

Hard minerals can be designed with no iron pollution, and the lining and grinding bodies are made of alumina ceramic, quartz, SILEX or special materials. ALPAs ball mill classifying production line with reasonable production capacity, large output, stable operation and stable product quality.

Ball mill can be divided into ball roller mill, cement ball mill according to its ball mill and classifying production line of alumina 10000 t y #183; ball mill and clay... Read more Full text of quot;Elementary chemistryquot; Internet Archive

Dry Ball Mill is a key equipment to grind the crushed materials in powdermaking production line. Grinded material discharges from outlet grit fluently. Ball grinding mill is Formed a closed system with air classifier. Coarse material will be back to ball mill to grind again, and qualified material will go to be packed by worker or packing machine.

China Manufacturer Mining Industry Quartz Silica Sand Ball Mill Classifying Line, Find details about China Silica Sand, Air Classifier from Manufacturer Mining Industry Quartz Silica Sand Ball Mill Classifying Line Weifang Guote Mining Equipment Co., Ltd.

Wet Grid Ball Mill . Capacity: Feed Size: 25 mm. Grid ball mill is widely used in smashing all kinds of ores and other materials, ore dressing and national economic departments like building and chemical industries etc. The size of ore shall not exceed 65mm and the best feed size is under 6mm.

ball mill and classifying production line of alumina t y. ball mill classifying production line quart crush. Ball Mill Production Line The ball mill is widely used in the fields of building materials mineral processing chemical industry electricity etc it can grind ores or Whatever your requirements, you ''ll find the perfect serviceoriented solution to match your specific needs with our help

Ball Mill And Classifying Production Line Of Alumina 10000 T Y. Ball mill and classifying production line of alumina t y ball mill classifying production line quart crush Ball Mill Production Line The ball mill is widely used in the fields of building materials mineral processing chemical industry electricity etc it can grind ores or Whatever your requirements you ll find the perfect service

Ultrafine grinding of sugar cane bagasse ash for application as pozzolanic admixture in concrete mill with short alumina and a hammer mill all operating in dry mode energy in a bond ball,Ball Mill And Classifying Production Line Of Alumina T Y From Ethiopia.

Ball Mill: Ball Mill is selected on the basis of hardness, grindability index of material, feed size, product size, capacity. Right selection of grinding ball and rod can improve grinding efficiency and reduce energy consumption. Classifier: Different series of classifier could be

Ceramic Ball mill [ Capacity ]: t/h [ Applicable Material ]: Dry ball mill is an important equipment to grind materials which is widely used in powder making production line including cement, feldspar, gypsum, newtype building material, refractory material, fertilizer, ore dressing of ferrous metal and nonferrous metal, glass ceramics, etc.

Alibaba offers 501 Ball Mill Ceramic Suppliers, and Ball Mill Ceramic Manufacturers, Distributors, Factories, Companies. There are 302 OEM, 281 ODM, 71 Self Patent. Find high quality Ball Mill Ceramic Suppliers on Alibaba.

Jul 18, 2019#0183;#32;Applicable Materials: Calcium carbonate (calcite, marble, lime stone, chalk), quartz, zircon, paillite, barite, kaoline, dolomite, magnesite, alumina, super fine

Cement Ball Mill Structure. When Ball Mill is working, raw material enters the mill cylinder through the hollow shaft of the feed. The inside of the cylinder is filled with grinding media of various diameters (steel balls, steel segments, etc.); when the cylinder rotates around the horizontal axis at a certain speed, Under the action of centrifugal force and friction force, the medium and the

ALPAs ball mill classifying production line, ball mill and classifier work well together, can complement each other, high efficiency, large output, stable operation and stable product quality. Influencing factors of Ball mill output

classifiers, such as screens, spiral classifiers, cyclones and air classifiers are used for classifying the discharge from ball mills. 4. Aluminum Ash Ball Mill is an efficient tool for grinding many materials into fine powder. Aluminum Ash Ball Mill is used to grind many kinds of mine and other materials, or to select the mine. 6.

WhatsApp)

WhatsApp)