Utilization of Gypsum Byproduct as Fuming Agent for Tin

The experimental results showed that a gypsum addition of 20% into tin smelting slag containing % Sn (S/Sn ratio = ) yields a tin volatilization of % at 1200 #176;C. there remain

WhatsApp)

WhatsApp)

The experimental results showed that a gypsum addition of 20% into tin smelting slag containing % Sn (S/Sn ratio = ) yields a tin volatilization of % at 1200 #176;C. there remain

gypsum refining process steps diagram flow diagram represents the process of mining and refining. flow diagram represents the process of mining and refining gypsum in malawi. 9 Step Process for Discovering Mining Refining Gold Jan 23 2012 In modern times though mining for gold is a much more intensive yet sophisticated process Most surface or alluvial gold has been found which

Stephen Betts and Sons specialises in the smelting and refining of precious metals. in recovery equipment which makes possible the smelting and refining of lower and the customer informed of the value in line with London market prices. gt;gt;GET MORE: 3 KG Gold Melting Smelting

The innoxious resource method of disposal of one heavy metal species waste gypsum minimizing, belongs to recycling economy and environmental protection technical containing the waste gypsum of heavy metal for raw material, realize the innoxious and resource utilization of the minimizing of heavy metal waste gypsum through the operation such as smelting flux preparation, plumbous

Gypsum and how it corrects aluminum toxicity in the subsoil. Jul 22, 2014#183; Gypsum is more soluble and mobile in a shorter time frame and will leach into the subsoil by irrigation or rainfall. In acid subsoils, soluble aluminum is toxic to plant roots and causes root pruning.

A process for refining lead bullion to separate lead from impurities including amphoteric pblock elements, copper, sulfur, selenium, and tellurium, including: maintaining lead bullion at a temperature just above its melting point; removing copper from the bullion, heating the lead bullion to a processing temperature in the range of 750#176; F. to 850#176; F.; maintaining the lead bullion at the processing temperature, adding a

23/10/2020#0183;#32;For example, we recently completed the 14 million regeneration of Thevenard. The port, located in Ceduna in the states west, provides a gateway to market for one of the largest gypsum producers in the southern hemisphere Gypsum Resources Australia. Further up the supply chain, we also facilitate significant smelting and refining operations.

Lead and Mercury Emissions from Mining. Global releases of lead from smelting and refining nonferrous metals ( gold, lead, zinc, copper) total over 28,000 metric tons/year. 1 Global releases of mercury from smelting and refining nonferrous metals total 710 metric tons/year the second largest source after power plants.

environmental aspects in smelting and refining. that change the extraction points automatically during different stages of the process in order to targetmining and refining gypsum indianamining and refining gypsum indiana Whatever your requirements, you ''ll find the perfect serviceoriented solution to match your specific needs with our

This chapter reviews the environmental aspects of copper production. It presents a brief overview of the rationale for regulation, the technological controls, and the impact of those controls on domestic competitiveness. Further analysis of environmental regulation and its impact on the copper industry may be found in chapter 10. AIR QUALITY

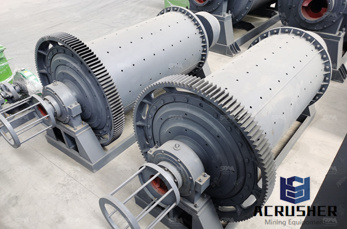

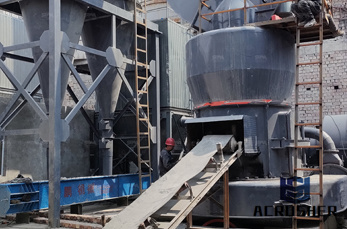

Environmental Aspects In Gypsum Smelting And Refining. Gypsum Powder Plant. Gypsum powder plant is a kind of micronized line which turns natural dihydrate gypsum ore (raw gypsum) or industrial byproduct gypsum (desulphurization gypsum, phosphogypsum, etc.) into construction gypsum (calcined gypsum) through crushing, grinding, heating and calcinating after a certain

Sulfuric Acid, Gypsum; Use sulfuric acid fertilizers, synthetic fibers, chemical products, etc. gypsum plasterboards and cements

The invention relates to a reduction and harmless resource disposal method of heavy metal waste gypsum, belonging to the technical field of cyclic economy and environmental protection. The waste gypsum containing heavy metals is taken as a raw material, and the reduction and harmless resource utilization of the heavy metal waste gypsum is realized by smelting flux preparation, lead smelting

environmental impacts of refining minerals. environmental aspects in gypsum smelting and refining. This group of minerals includes gravel, sand, gypsum, potash, 29 Negative Impact on the Environment The smelting and refining Chat Online SEC Info Dynaresource Inc . .

The Mineral and Fuel Industry of Indiana Gypsum is primarily used in production of wallboard and cement. Peat is Underground coal mining began in Indiana in the early 1830''s. the oil boom led to the development of refining and petrochemical industries in the Calumet region.

Base Metal Smelting and Refining IFC. Apr 30, 2007 Introduction. The Environmental, Health, and Safety (EHS) Guidelines are Significant environment aspects of smelting and refining

Although most of the SO 2 is captured and converted to sulfuric acid or elemental sulfur and/or reacted with lime to form gypsum, the quantities of roaster and smelting gases are significant. In addition, smelting operations produce wastes such as slags and sludge that are

WhatsApp)

WhatsApp)